The Miller Sensing Edge MT33 is a crucial component designed to enhance safety and efficiency in a variety of industrial settings. This versatile product offers immediate feedback to operator controls, triggering prompt responses to either stop or reverse door operations upon light contact. Crafted with precision, the MT33 sensing edge boasts a robust vinyl jacket that ensures durability and longevity.

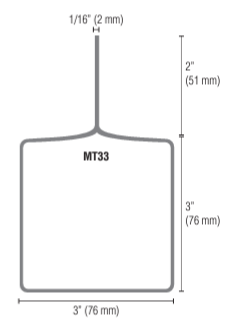

Ideal for applications such as rolling fire doors, rolling steel doors, and material handling systems, the MT33 excels in diverse environments. Its flexible design allows it to seamlessly adapt to irregularities in the floor, ensuring a secure fit in various setups. The MT33 comes in a standard 3” width by 3” height, providing optimal coverage for surfaces that are 2 inches thick or more.

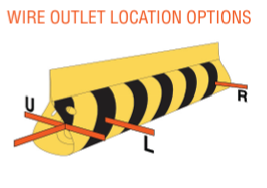

This innovative sensing edge is customizable to meet user preferences, offering options for color, length, and outlet location. The patented Alumaglas™ technology incorporated in the design guarantees superior performance, especially for electric applications. Additionally, the MT33 features sealed assembly that is impervious to dust and debris, underscoring its reliability and longevity.

Manufactured in the US and backed by a 1-year warranty, the MT33 is a dependable solution for businesses seeking high-quality sensing edges. This UL 325 Recognized Component adheres to stringent industry standards, ensuring compliance and peace of mind. Elevate your operational efficiency and safety protocols with the Miller Sensing Edge MT33 – a premium choice for industrial door systems.

The MT sensing edge product line consists of three standard models: MT21 (2”W x 1”H), MT22 (2”W x 2”H), and MT33 (3”W x 3”H). When touched lightly, the sensing edge will send an immediate signal to operator controls to stop and/or reverse door operation. The MT edge switch is covered in a durable vinyl jacket. The top tab inserts between the double-L angle bottoms bars on a rolling door. These sensing edges are flexible and can conform to irregularities in the floor.

APPLICATIONS · Rolling fire doors · Rolling steel doors · Material handling systems

FEATURES · Optimum size for 2+ inch thick surfaces · Custom manufactured to user specifications for color, length, and outlet location · Three standard models: MT21 (2”W x 1”H), MT22 (2”W x 2”H), MT33 (3”W x 3”H) · 5-6 inch end flaps create a complete seal and can be trimmed for custom fit · Extended color options including yellow chemical resistant XR5 jacket · Flexible and will conform to floor irregularities · Sealed assembly impervious to dust and debris · Patented Alumaglas™ for superior performance (electric option) · UL 325 Recognized Component · 1-year warranty · Made in US

Dimensions

End flaps extend 5-6 inches beyond active edge

Monitored Devices Guidelines For UL325 Listed Operators Built After August 29th, 2010 that have a Monitored Circuit

For older units Prior and other applications in most cases a Non Monitored edge is used

Please confirm with manufacture before ordering as edges are all edges are custom made and Not returnable

Monitored Sensing Edge Designator

T1 is a 8.2K Ohm Resistor Green Color Code Typically used for European Operators

T2 is a 10K Ohm Resistor Blue Color Code Typically used by the Following Manufactures

Cornell / US Gear, Liftmaster / Chamberlain, Linear, Manaras, Micanan / Napoleon Lynx,

Raynor, VE Power Door, Cookson,, Lawrence

T3 Diode Capacitor Red Color Code Used for Overhead Door Corporation units

T4 Capacitor White Color Code for Linear (Transmitter)

T5 6.8K Ohm Resistor Orange Color Code Custom Applications

T6 270K Ohm Resistor Violet Color Code Liftmaster CPS Board