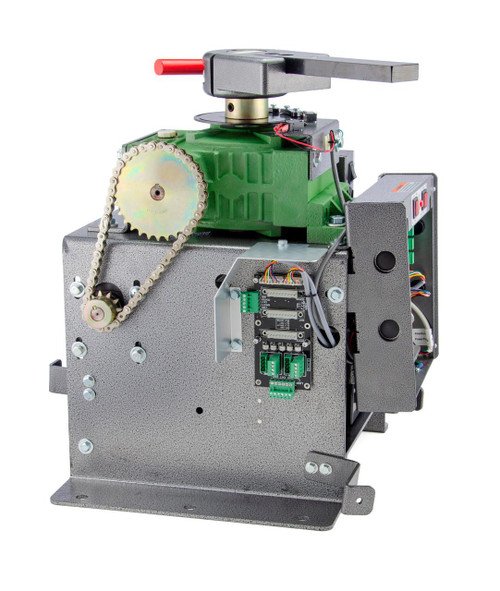

The CSW24UL Commercial Swing Gate Operator with Battery Backup is the perfect solution for your swing gates. With its advanced technology and durable construction, this gate opener ensures smooth and secure operation. The Liftmaster CSW24UL offers superior performance and convenience, allowing you to effortlessly control access to your property. Trust in the CSW24UL gate opener for reliable performance and peace of mind.

New Liftmaster CSW24UL (replaces older model CSW24VDC and CSW24U)

Commercial swing gate operator with battery backup system

Updated unit complies with new UL325 code revised Aug 2018

System now requires monitored secondary entrapment devices

unit will include LMRRU safety photo eye

***Can only be used on level swinging gate

LiftMaster CSW24UL Gate Operator – Heavy-Duty Slide Gate Automation

The LiftMaster CSW24UL is a high-performance, UL 325-compliant gate operator designed for commercial, industrial, and high-traffic residential applications. Built to handle continuous operation, the CSW24UL is ideal for properties that demand durability, speed, and reliability.

Key Features:

-

24VDC Continuous Duty Motor – Provides quiet, powerful performance for heavy gates.

-

Battery Backup Included – Keeps the gate running during power outages.

-

UL 325 Safety Standards Compliant – Ensures top-tier safety with built-in safety sensors and soft start/stop technology.

-

Gate Capacity – Supports gates up to 18 feet and 1,200 lbs.

-

Smart Technology – Compatible with MyQ® for remote access and monitoring via smartphone.

Why Choose the CSW24UL?

-

Designed for heavy-duty swing gate applications

-

Smooth, quiet operation with reduced wear and tear

-

Integrated Security+ 2.0® for encrypted wireless access control

-

Ideal for gated communities, commercial properties, or secured facilities

Whether you're upgrading an old system or installing a new gate, the LiftMaster CSW24UL offers a reliable, secure, and smart solution.

MODEL CSW24UL High-Traffic Commercial DC Swing Gate Operator with Battery Backup The LiftMaster Elite Series model CSW24UL is engineered for a million cycles in high-cycle, heavy-duty applications. A Battery Backup System provides uninterrupted access when the power is out, and Security+ 2.0 technology virtually eliminates radio interference. It also features integrated MyQ technology and the industry's only standard blue-tooth wireless dual gate communication system. The CSW24UL is rated for gates 18 ft. long or 1,200 lbs. Battery Backup System provides uninterrupted access when the power is out Provides up to 7 days or 100 cycles on battery backup. Also powers safety and ancillary devices. Provides 2x the range of standard remote controls Our patented Security+ 2.0 Technology provides two times the range of standard remote controls and virtually eliminates radio interference. An on-board radio receiver is included with the CSW24UL. It holds up to 50 remotes and is compatible with HomeLink® version 4 and higher. Wireless dual gate communication prevents driveway scars and expensive wiring The on-board radio receiver provides a single remote control solution for gates and additional access points. It also features the industry's only standard wireless dual gate communication system that saves installation time and cost and eliminates unsightly scars from cutting driveways to run conduit for primary/secondary communication wiring.

Operators are to be installed by authorized Liftmaster technicians only.

Warranty

5 years Commercial

7 Years Residential

Liftmaster CSW24VDC Installation Manual (click here)

Click here for Brochure

Battery Backup Secures and safeguards your property by providing up to 146 cycles or up to 24 days of standby power when the power is down.

Security+2.0® Access your property quickly with Security+2.0® Technology that utilizes a tri-band signal that virtually eliminates interference and offers extended range each time the remote control is used.

MyQ® Securely control and monitor your Gate Operator from anywhere and get activity notifications through the MyQ® app.

P3 Motors LiftMaster has designed its own purpose built motor to meet the exact requirements needed to open and close your gate.

Features

LED DIAGNOSTIC DISPLAY Simplifies installation and troubleshooting.

SOLAR-READY ULTRA-RELIABLE SYSTEM Simple solar conversion delivers power when you need it most and is extremely power efficient at all other times to maximize solar performance.

PROGRAMMABLE AUXILIARY RELAYS Easily add additional features, such as warning lights/alarms.

BI-PART DELAY Monitors and adjusts speed and position of each wing to ensure primary gate closes last.

SYNCHRONIZED CLOSE Simultaneously closes gates.

PRE-MOTION WARNING ALARM Activates onboard alarm three seconds prior to gate motion.

ANTI-TAILGATE Prevents unauthorized access. Gate will pause when closing as vehicle pulls onto interrupt loop or breaks photo beam. Once vehicle backs up, gate will continue to close.

QUICK CLOSE Closes the gate immediately after a vehicle pulls off the interrupt loop.

HOMELINK® COMPATIBLE Version 4 and higher.

SECURITY+ 2.0® ON-BOARD RADIO RECEIVER Up to 50 remote controls (unlimited with 811LM/813LM).ENGINEERED FOR MORE THAN 1 MILLION CYCLES, OUR P3 Motor is designed to perform in the most demanding environments.

HEAVY-DUTY COMMERCIAL GEAR DRIVEN TRANSMISSION Provides unsurpassed reliability.

SOFT START/STOP and MID TRAVEL REVERSAL extends operator and hardware life in high-cycle and heavy-gate applications.

WIRELESS DUAL-GATE COMMUNICATION Eliminates expensive conduit costs and unsightly driveway scars.

FIRE DEPARTMENT COMPLIANCE allows gate to auto open upon loss of AC power or battery depletion

QUICK CLOSE/ANTI-TAILGATE quickly secures property, preventing unauthorized access.

SURGE SUPPRESSION provides industrial surge and lightning protection against strikes up to 50 feet away

CSW24UL Error Codes

00 Normal Operation No Action Required

31 Main control board has experienced an internal failure. Disconnect all power, wait 15 seconds, then reconnect power (reboot). If issue continues, replace main control board.

34 Absolute Position Encoder Error, not getting position information from encoder Check APE assembly and wiring connections. Replace the APE assembly if necessary.

35 Max-Run-Time Exceeded Error Check for an obstruction, then reprogram the limits.

36 Product ID Error Was the control board just replaced? If so, erase limits, enter limit setup mode and set limits. If not, disconnect all power, wait 15 seconds, then reconnect power before changing product ID harness.

37 Product ID Failure Unplug product ID harness then plug back in. Disconnect all power, wait 15 seconds, then reconnect power before replacing product ID harness.

38 Hard Stop Limit (Arm 1) Limit may be set too tightly against a non-resilient hard stop (re-adjust limit). Operator may be at end of travel (re-adjust mounting).

40 Battery overvoltage Too much voltage on the battery. Check harness. Make sure there is NOT a 24V battery on a 12V system.

41 Battery overcurrent Possible short of the battery charge harness. Check harness. Make sure you do NOT have a 12V battery on a 24V system.

42 No battery at boot up Check battery connections and installation. Replace batteries if depleted to less than 20V on a 24V system or less than 10V on a 12V system.

Make sure there is NOT a single 12V battery on a 24V system.

43 Exit Loop Error Failure or missing loop (SHORT or OPEN - LiftMaster Plug-in Loop Detector only) Check loop wiring throughout connection. May be a short in the loop, or an open connection in the loop.

44 Shadow Loop Error

45 Interrupt Loop Error

46 Wireless edge battery low Replace batteries in wireless edge.

50 Run-Distance Error The limits are less than the minimum requirement or longer than what was learned. Check limit positions and proper switch function. Run- distance can be re-learned by setting the handing again.53 Brownout occurred AC/DC board supply dipped below allowable level. Review power supply and wiring. If rebooting, ensure enough time for discharge of power to force a fresh boot.

54 Wireless Second Operator Communication Error Check the second operator for power. If OFF, restore power and try to run the system. If powered, deactivate the wireless feature and then re-learn the second operator.

60 Minimum number of monitored entrapment protection devices not installed. Review monitored entrapment protection device connections. Slide gate operators require a minimum of two external safety devices; one in the close and one in the open direction.

61 CLOSE EYE/INTERRUPT held more than 3 minutes

Check wired input on main control board; check for alignment or obstruction.

62 CLOSE EDGE held more than 3 minutes

63 OPEN EYE/EDGE held more than 3 minutes

64 CLOSE EYE/INTERRUPT held more than 3 minutes Check wired input on expansion board; check for alignment or obstruction.65 CLOSE EYE/EDGE held more than 3 minutes Check wired input on expansion board; check for alignment or obstruction.

66 OPEN EYE/EDGE held more than 3 minutes Check wired input on expansion board; check for alignment or obstruction.67 Wireless edge triggered more than 3 minutes Check wired input for wiring issue or obstruction.

68 Wireless edge loss of monitoring Check wireless edge inputs.

69 Wireless edge triggered IF an obstruction occurred, no action required. If an obstruction did NOT occur, check inputs and wiring.

70 CLOSE EYE/INTERRUPT triggered, causing reversal, preventing close, or resetting TTC IF an obstruction occurred, no action required. If an obstruction did NOT occur, check alignment, inputs, and wiring on main control board71 CLOSE EDGE triggered, causing reversal, NO preventing close, or canceling TTC

72 OPEN EYE/EDGE triggered, causing reversal or preventing opening

73 CLOSE EYE/INTERRUPT triggered, causing reversal, preventing close, or resetting TTC IF an obstruction occurred, no action required. If an obstruction did NOT occur, check alignment, inputs, and wiring on expansion board.74 CLOSE EYE/EDGE triggered, causing reversal and preventing close or canceling TTC

75 OPEN EYE/EDGE triggered, causing reversal or preventing opening

80 Close input (EYE/EDGE) communication fault from other operator Check inputs and communication method between operators, either wired bus or radio. Ensure operator is powered. May have to erase the wireless communication and reprogram the two operators.

81 Open input (EYE/EDGE) communication fault from other operator

82 Close input (EYE/EDGE) communication fault (expansion board) Check the connections between the main board and the expansion board.

83 Open input (EYE/EDGE) communication fault (expansion board)84 Non-monitored device detected on the wireless safety system Non-monitored contact closure devices are not supported. Make sure connected devices are monitored. Check edges for proper orientation and resistive end cap connection.

91 Force Reversal (Operator 1) Check for obstruction. If no obstruction, check that the mechanical assembly is engaged and free to move. See section on Limit and Force Adjustment, and Obstruction Test.

93 RPM / STALL Reversal (Operator 1) Check for obstruction. If no obstruction, check the operator wiring and that the mechanical assembly is engaged and free to move. Replace APE assembly.

99 Normal Operation No action required

![Liftmaster CSW24UL Commercial Swing Gate Operator with Battery Backup [CSW24ULMC] Liftmaster CSW24UL Commercial Swing Gate Operator with Battery Backup [CSW24ULMC]](https://cdn11.bigcommerce.com/s-32eq2wsbti/images/stencil/500x659/products/7977/231391/liftmaster-csw24ul-commercial-swing-gate-operator-with-battery-backup-csw24ulmc-csw24ul__68196.1724086900.jpg?c=2)

![Liftmaster CSW24UL Commercial Swing Gate Operator with Battery Backup [CSW24ULMC] Liftmaster CSW24UL Commercial Swing Gate Operator with Battery Backup [CSW24ULMC]](https://cdn11.bigcommerce.com/s-32eq2wsbti/images/stencil/50x50/products/7977/231391/liftmaster-csw24ul-commercial-swing-gate-operator-with-battery-backup-csw24ulmc-csw24ul__68196.1724086900.jpg?c=2)

![Liftmaster CSW24UL Commercial Swing Gate Operator with Battery Backup [CSW24ULMC] Liftmaster CSW24UL Commercial Swing Gate Operator with Battery Backup [CSW24ULMC]](https://cdn11.bigcommerce.com/s-32eq2wsbti/images/stencil/50x50/products/7977/231343/liftmaster-csw24ul-commercial-swing-gate-operator-with-battery-backup-csw24ulmc-csw24ul__04680.1724086843.jpg?c=2)

![Liftmaster CSL24UL Commercial Slide Gate Operator with Battery Backup [CSL24ULMC] Liftmaster CSL24UL Commercial Slide Gate Operator with Battery Backup [CSL24ULMC]](https://cdn11.bigcommerce.com/s-32eq2wsbti/images/stencil/500x659/products/8309/233181/liftmaster-csl24ul-commercial-slide-gate-operator-with-battery-backup-csl24ulmc-csl24ul__71757.1724089762.jpg?c=2)

![Liftmaster RSW12UL Residential Swing Gate Operator with Battery Backup [RSW12ULMC] Liftmaster RSW12UL Residential Swing Gate Operator with Battery Backup [RSW12ULMC]](https://cdn11.bigcommerce.com/s-32eq2wsbti/images/stencil/500x659/products/11207/229759/liftmaster-rsw12ul-residential-swing-gate-operator-with-battery-backup-rsw12ulmc-rsw12ul__81203.1721411260.jpg?c=2)