|

|  | |

|  | |

|

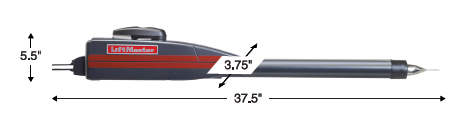

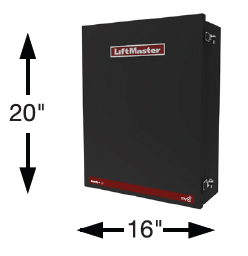

Dimensions

31 Main control board has experienced an internal failure. Disconnect all power, wait 15 seconds, then reconnect power (reboot). If issue continues, replace main control board.

32 Linear Drive Disengaged (Arm 1) Disengage then re-engage arm. Check wiring and connections.

33 Linear Drive Disengaged (Arm 2)

35 Max-Run-Time Exceeded Error Check for an obstruction, then reprogram the limits.

36 Product ID Error Was the control board just replaced? If so, erase limits, enter limit setup mode and set limits. If not, disconnect all power, wait 15 seconds, then reconnect power before changing product ID harness.

37 Product ID Failure Unplug product ID harness then plug back in. Disconnect all power, wait 15 seconds, then reconnect power before replacing product ID harness.

38 Hard Stop Limit (Arm 1) Limit may be set too tightly against a non-resilient hard stop (re-adjust limit). Operator may be at end of travel (re-adjust mounting).

39 Hard Stop Limit (Arm 2)

40 Battery overvoltage Too much voltage on the battery. Check harness. Make sure there is NOT a 24V battery on a 12V system.

41 Battery overcurrent Possible short of the battery charge harness. Check harness. Make sure you do NOT have a 12V battery on a 24V system.

42 No battery at boot up Check battery connections and installation. Replace batteries if depleted to less than 20V on a 24V system or less than 10V on a 12V system. Make sure there is NOT a single 12V battery on a 24V system

43 Exit Loop Error Failure or missing loop (SHORT or OPEN - LiftMaster Plug-in Loop Detector only) Check loop wiring throughout connection. May be a short in the loop, or an open connection in the loop.

44 Shadow Loop Error

45 Interrupt Loop Error

46 Wireless edge battery low Replace batteries in wireless edge.

51 Pass-point not detected (Arm 1) Check yellow pass-point wiring. If limits are not accurate, reprogram.

52 Pass-point not detected (Arm 2)

53 Brownout occurred AC/DC board supply dipped below allowable level. Review power supply and wiring. If rebooting, ensure enough time for discharge of power to force a fresh boot.

YES

54 Wireless Second Operator Communication Error Check the second operator for power. If OFF, restore power and try to run the system. If powered, deactivate the wireless feature and then re-learn the second operator.

YES

60 Minimum number of monitored entrapment protection devices not installed. Review monitored entrapment protection device connections. This swing gate operator will operate only after installation of a minimum of one external safety device in either the open or close direction.

61 CLOSE EYE/INTERRUPT held more than 3 minutes

Check wired input on main control board; check for alignment or obstruction.

62 CLOSE EDGE held more than 3 minutes

63 OPEN EYE/EDGE held more than 3 minutes

64 CLOSE EYE/INTERRUPT held more than 3 minutes

Check wired input on expansion board; check for alignment or obstruction.

65 CLOSE EYE/EDGE held more than 3 minutes

66 OPEN EYE/EDGE held more than 3 minutes

67 Wireless edge triggered more than 3 minutes Check wired input for wiring issue or obstruction.

68 Wireless edge loss of monitoring Check wireless edge inputs.

69 Wireless edge triggered IF an obstruction occurred, no action required. If an obstruction did NOT occur, check inputs and wiring.

70 CLOSE EYE/INTERRUPT triggered, causing reversal, preventing close, or resetting TTC IF an obstruction occurred, no action required. If an obstruction did NOT occur, check alignment, inputs, and wiring on main control board

71 CLOSE EDGE triggered, causing reversal, NO preventing close, or canceling TTC

72 OPEN EYE/EDGE triggered, causing reversal or preventing opening

73 CLOSE EYE/INTERRUPT triggered, causing reversal, preventing close, or resetting TTC IF an obstruction occurred, no action required. If an obstruction did NOT occur, check alignment, inputs, and wiring on expansion board.

74 CLOSE EYE/EDGE triggered, causing reversal and preventing close or canceling TTC

75 OPEN EYE/EDGE triggered, causing reversal or preventing opening

80 Close input (EYE/EDGE) communication fault from other operator Check inputs and communication method between operators, either wired bus or radio. Ensure operator is powered. May have to erase the wireless communication and reprogram the two operators.

81 Open input (EYE/EDGE) communication fault from other operator

82 Close input (EYE/EDGE) communication fault (expansion board) Check the connections between the main board and the expansion board.

83 Open input (EYE/EDGE) communication fault (expansion board)

84 Non-monitored device detected on the wireless safety system Non-monitored contact closure devices are not supported. Make sure connected devices are monitored. Check edges for proper orientation and resistive end cap connection.

91 Force Reversal (Operator 1) Check for obstruction. If no obstruction, check that the mechanical assembly is engaged and free to move. See section on Limit and Force Adjustment, and Obstruction Test.

92 Force Reversal (Operator 2)

93 RPM / STALL Reversal (Operator 1) Check for obstruction. If no obstruction, check the operator wiring and that the mechanical assembly is engaged and free to move. Replace APE assembly.

94 RPM / STALL Reversal (Operator 2)

99 Normal Operation No action required

![Liftmaster LA400 for single piece gate includes control box [LA400PKGULMC] Liftmaster LA400 for single piece gate includes control box [LA400PKGULMC]](https://cdn11.bigcommerce.com/s-32eq2wsbti/images/stencil/500x659/products/15252/227098/liftmaster-la400-for-single-piece-gate-includes-control-box-la400pkgulmc-la400pkgul__08986.1725051299.jpg?c=2)

![Liftmaster LA400 for single piece gate includes control box [LA400PKGULMC] Liftmaster LA400 for single piece gate includes control box [LA400PKGULMC]](https://cdn11.bigcommerce.com/s-32eq2wsbti/images/stencil/50x50/products/15252/227098/liftmaster-la400-for-single-piece-gate-includes-control-box-la400pkgulmc-la400pkgul__08986.1725051299.jpg?c=2)